Guest Post by Rehman Lund, 2021-2022 Sustainability Leadership Fellow, and Ph.D. Student in the Department of Civil and Environmental Engineering at Colorado State University

Does all the water in the irrigation canals make it to the farms?

During the conveyance of agricultural water via irrigation canals, a large amount of water leaves the system in the form of canal seepage and joins the adjoining groundwater. This, of course, depends on a wide variety of factors such as the type of soil the canals are carved through, the head gradient between the canal and the adjoining groundwater, and the quality of the water being transported. Regardless, a vast majority of the irrigation canals around the globe experience seepage losses. These losses are more prevalent in developing countries such as South Asia and Sub-Saharan Africa and less prevalent in the developed world including North America and Europe (Jagermeyr et al. 2016). Nonetheless, some parts of the United States exhibit substantial seepage losses that are comparable to those in the developing world (Lund et al. 2021).

Why controlling canal seepage is important?

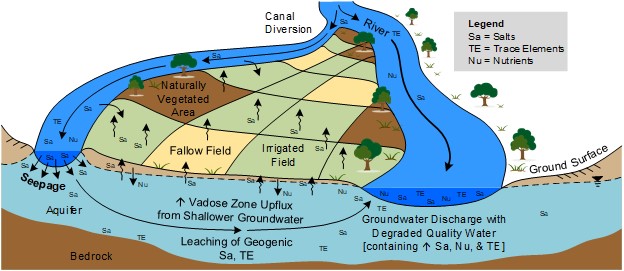

Along with the loss of valuable water, seepage results in some negative impacts on the environment. The seeped water carries a variety of geogenic salts while making its way to groundwater, thus contaminating the groundwater quality. Also, such geogenic trace elements are transported back to (i) freshwater bodies in the form of return flows (Gates et. Al. 2012) and (ii) the near-surface soils because of the evaporative concentration, leading to soil salinization. The diminished water and soil quality, as a result, decline the crop yields in the long term (Zorb et al. 2019). Figure 1 shows the processes leading to agro-environmental degradation caused by canal seepage.

Why traditional canal seepage control techniques are not a good option?

Canal seepage is commonly controlled by lining the irrigation canals with permanent liners such as concrete, asphalt, and geomembranes. Fewer permanent liners such as water-soluble polymers, bentonite clay, etc. have also been found useful, yet not applied on a large scale. The permanent liners exhibit as high as 97% reduction in seepage (USDA 1997). However, the biggest hurdle with those is the hefty upfront cost that can exceed the value of saved water in various applications (Wichelns and Oster 2006). Additionally, these liners act as permanent barriers to prevent seepage, however, seepage can help replenish the groundwater when water is plentiful. Therefore, permanent liners are not capable of working on an as-needed basis.

Use of polymer sealants for mitigating canal seepage

Some field research studies performed in the US, Pakistan, and Chile show that synthetic polymer sealants can have great potential to reduce canal seepage (Lund et al. 2021, Martin and Gates 2014, and Uribe et al. 2013). These sealants are flocculants; upon applying the polymers in granular form to the canal water surfaces, the polymers interact with the suspended particulate matter in the canal water to form sediment-polymer flocs. The flocs, upon growing large enough, settle down and clog the canal bed and sides. Nevertheless, some environmentalists do not welcome the direct application of polymers given some possible yet rare environmental considerations (Young et al. 2007).

Way forward

Recently, our team at CSU has been investigating some environmental-friendly substitutes for synthetic polymers that are almost equally economical. We have performed some experiments using various bio-derived polymers in the laboratory and downselected Xanthan Gum for the field-scale experiments. Figure 2 shows the Xanthan Gum application. We applied Xanthan Gum in powder form on the Larimer and Weld Canal in Colorado and the post-application seepage measurements revealed that Xanthan Gum reduced canal seepage by almost 70%. We are in the process of refining our application methodology and conducting some additional field experiments to gain a deeper understanding of the field seepage reduction mechanisms.

References

Jägermeyr, J., Gerten, D., Schaphoff, S., Heinke, J., Lucht, W., & Rockström, J. (2016). Integrated crop water management might sustainably halve the global food gap. Environmental Research Letters, 11(2), 025002.

Lund, A. R., Martin, C. A., Gates, T. K., Scalia IV, J., & Babar, M. M. (2021). Field evaluation of a polymer sealant for canal seepage reduction. Agricultural Water Management, 252, 106898.

Martin, C. A., & Gates, T. K. (2014). Uncertainty of canal seepage losses estimated using flowing water balance with acoustic Doppler devices. Journal of Hydrology, 517, 746-761.

United States Department of Agriculture (USDA). (1997). Irrigation guide, Natural Resources Conservation

Service, USDA. 210-vi-NEH, Sept. 1997.

Uribe, H., Figueroa, R., & Llanos, L. (2013). Assessment of linear anionic polyacrylamide application to irrigation canals for seepage control. Journal of Agricultural Engineering, 44(s2).

Wichelns, D., and Oster, J. (2006). Sustainable irrigation is necessary and achievable,

but direct costs and environmental impacts can be substantial. Agricultural Water

Management, 86(1-2), 114-127.

Young, M. H., Tappen, J. J., Miller, G. C., Carroll, S., & Susfalk, R. B. (2007a). Risk characterization: Using linear anionic polyacrylamide (LA-PAM) to reduce water seepage from unlined water delivery canal systems. Desert Research Institute.

Zörb, C., Geilfus, C. M., and Dietz, K. J. (2019). Salinity and crop yield. Plant biology, 21, pp. 31-38.